Custom-fit prosthetics for people who have lost limbs are costly, inflexible, and time-consuming to make. A team in Switzerland have come up with a solution that could not only revolutionise prosthetics but humanoid robotics as well.

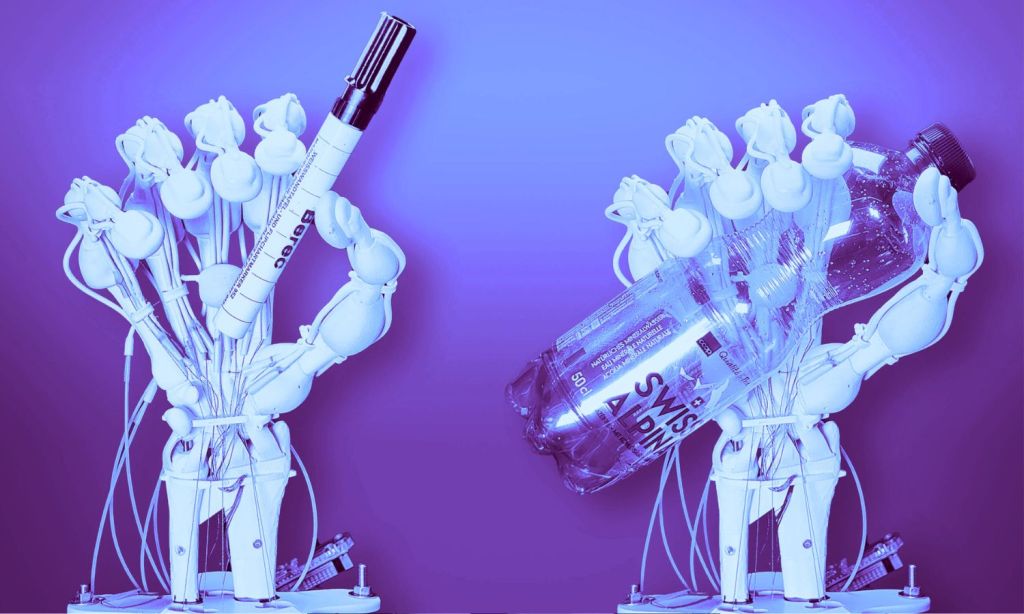

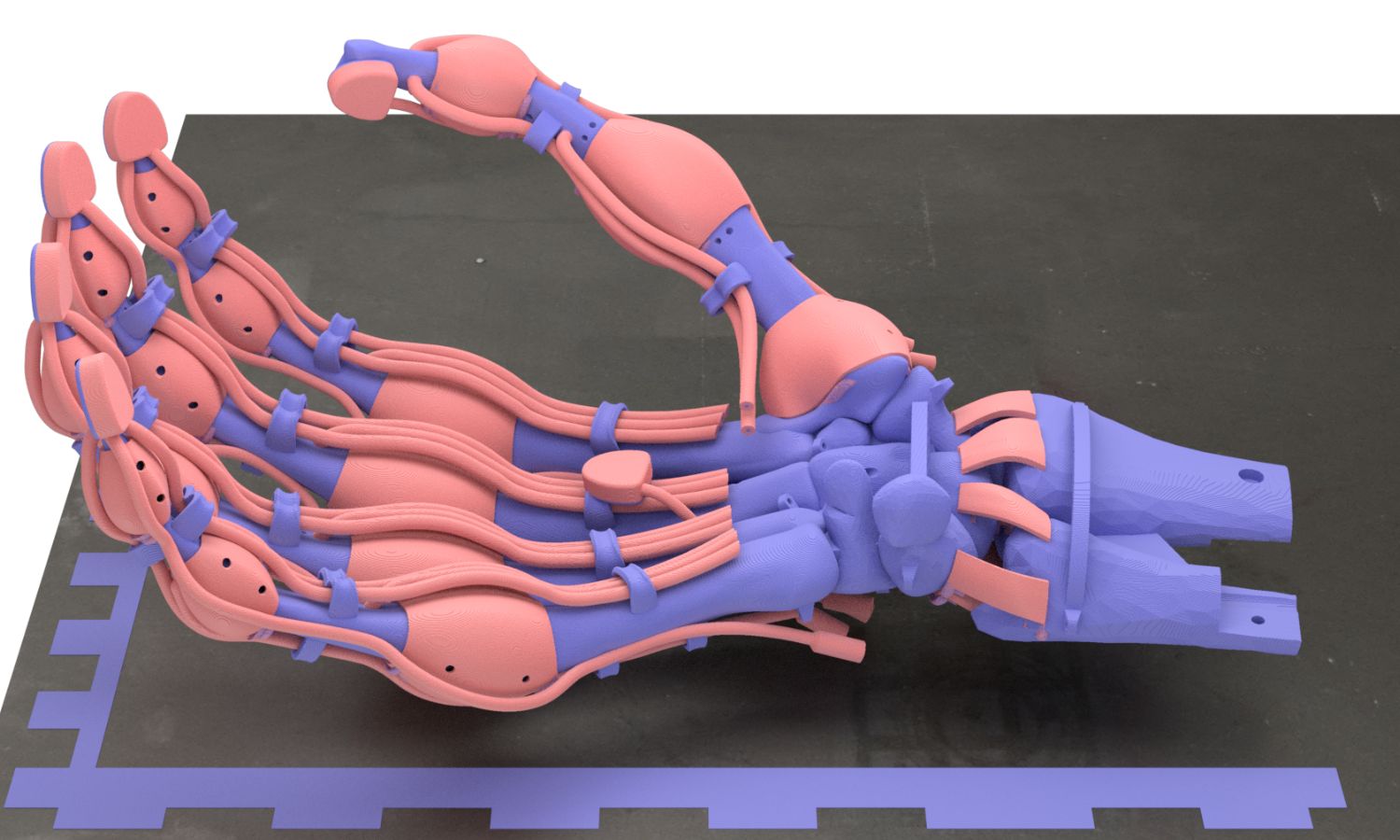

Researchers from robotics firm ETH Zurich and Inkbit, a startup based out of MIT, have developed a way to rapidly print flexible, human-like limbs. They’ve demonstrated this breakthrough with 3D-printed robotic hands complete with tendons, ligaments, and bones made up of several different materials. Analysts describe their work as having achieved “the impossible.”

The problem with 3D printing currently is that you’re often restricted to using quickly hardening or ‘fast-curing’ materials like hard plastics. These aren’t ideal for prosthetics as the hard materials don’t play well with the soft, squishy interiors of humans. By switching up the printing methods, they’ve been able to incorporate softer materials that behave more like human tissue.

“We wouldn’t have been able to make this hand with the fast-curing polyacrylates we’ve been using in 3D printing so far,” explained Thomas Buchner, a doctoral student at ETH Zurich.

“We’re now using slow-curing thiolene polymers. These have very good elastic properties and return to their original state much faster after bending than polyacrylates.”

3D printers work layer by layer to build up a physical object, curing the printed material with a UV lamp and then scraping back imperfections as they go. Using 3D laser scanning technology to account for imperfections as the printer goes, the team has been able to rapidly speed up the process and incorporate softer materials that don’t need to be scraped back.

“Robots made of soft materials, such as the hand we developed, have advantages over conventional robots made of metal. Because they’re soft, there is less risk of injury when they work with humans, and they are better suited to handling fragile goods,” Katzschmann said.

The team have published their work in the journal Nature and plans to use it to develop even more complex printing abilities.

The World Health Organisation estimated in 2017 that there are around 35-40 million people who require prosthetics around the world, but only around 10% of them have access to the support they need. This is a major problem in developing nations in the global South where conflict is a major driver of disability. Cost is, of course, one of the biggest barriers to access.

In the mid-2010s, 3D-printed prosthetic limbs were hailed as the “next revolution in medicine”. Because 3D printing is comparably cheap and instructions can be shared online, there is a vast and growing network of people out there who are using their 3D printers to supply people with prosthetics.

The organisation Enabling the Future says that it has a community of 40,000 volunteers with access to 3D printers in over 100 countries. Together, they have delivered an estimated 10-15,000 hands and arms to people in need, completely free of cost.

A custom metal prosthetic limb can cost thousands of dollars and, for young people, needs to be replaced every few years as they grow. A 3D printed version might cost $60 and can be replaced as often as required.

This latest breakthrough, with the ability to 3D print using soft materials “in minutes”, is therefore a much-needed and hugely beneficial advancement.

Related: Scientists Found a Way to Keep a Brain Alive Outside the Body

Related: They’re Growing Mice Babies in Space — Humans Will Take Much Longer

Read more stories from The Latch and subscribe to our email newsletter.